A well-made hot foil machine is one of the most valuable investments a design-led business can make. If you produce luxury packaging or stationery, your press should deliver consistency and precision every time. But with a wide range of options available, choosing the right hot foil machine isn’t always straightforward, particularly for small businesses where every decision needs to be intentional.

What Does a Hot Foil Machine Do?

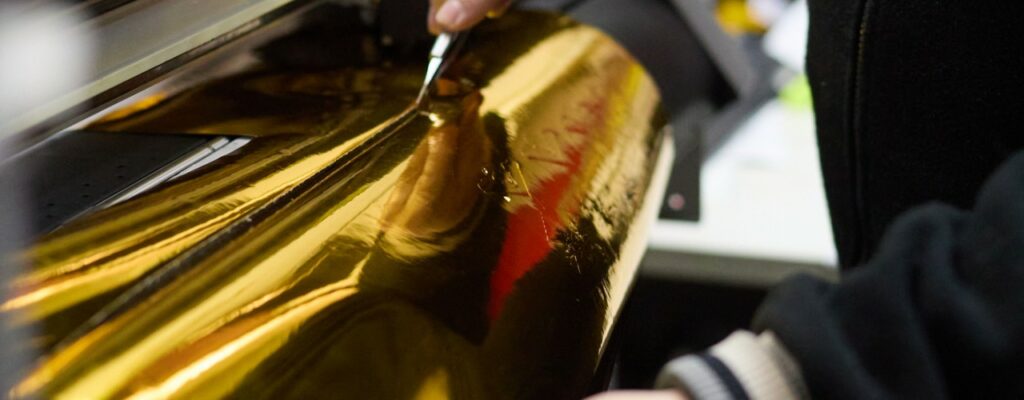

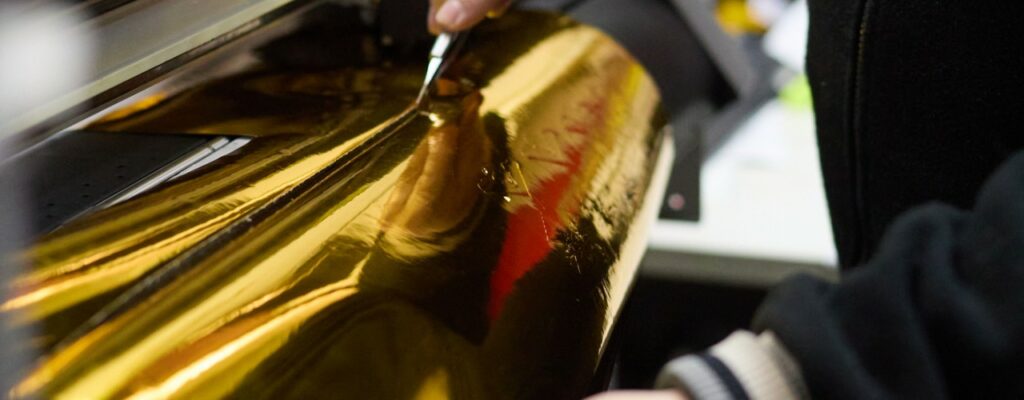

A hot foil machine applies a layer of foil to a substrate using heat and pressure. It uses a metal die to press the foil into the material, creating an appealing, high-contrast finish. Foil comes in a range of finishes and colours that allow brands to create distinctive, professional-quality print finishes on a variety of surfaces.

Hot foil stamping is widely used in luxury packaging, artisan goods, bookbinding, and premium stationery. For small business owners, it provides a reliable way to produce short-run, high-impact work without relying on mass-production methods.

Key Considerations When Choosing a Hot Foil Machine

1. Format and Application Type

Before looking at models, you’ll need a clear understanding of what you’re foiling and how often. Are you producing packaging for small-batch products? Branding swing tags? Adding logos to notebooks or cards?

The type of application influences the machine size and configuration you need. Smaller presses are ideal for flat stationery, tags, or labels. If you’re working with boxes, pouches, or multi-layered packaging, you may need a machine with a larger platen and adjustable height settings.

2. Manual, Semi-Automatic or Pneumatic?

There are three common types of hot foil machines:

- Manual presses are operated by hand, making them ideal for short-run projects, startups, and design studios that want tactile control without high energy costs

- Semi-automatic presses offer more speed and consistency, with an electric motor to assist pressure application while still allowing operator control

- Pneumatic machines use air pressure to deliver consistent results with minimal manual input. They’re suitable for higher volumes or businesses scaling up their foil production

Each type has its place. Manual machines are perfect for hands-on makers. Semi-automatic presses strike a balance for growing businesses. Pneumatic machines are better suited for long, repeated runs.

3. Compatibility With Materials

Not all hot foil machines perform equally across all substrates. If you plan to foil textured card, recycled stock, leather, or packaging board, make sure the machine can deliver enough pressure and temperature range to handle those surfaces cleanly.

At Metallic Elephant, we advise our customers based on their most used materials to ensure a good fit from day one. Some setups are better suited to smoother stocks, while others can be adapted for rougher textures with deeper dies and adjusted dwell times.

4. Precision and Adjustability

For artisan brands, consistency is essential. Look for a machine that offers adjustable temperature, pressure, and dwell time. These controls will allow you to refine each impression to the material and foil in use.

A reliable hot foil machine should deliver identical results across a full batch, without needing constant adjustment. Misalignment, uneven foil transfer, or pressure inconsistencies can undermine the quality of your finished product and waste materials.

5. Build Quality and Maintenance

The longevity of your machine depends on how it’s made. A solid, well-constructed press will give you years of reliable service with minimal downtime. Avoid machines that feel flimsy or overcomplicated.

At Metallic Elephant, every hot foil machine is built by hand in our UK workshop using British engineering principles. Our machines are made to last, with durable parts and a low-maintenance design that suits small studios as well as busy production environments.

Features to Prioritise

If you’re comparing models, these features are worth prioritising:

- Easy-to-adjust pressure and temperature settings

- Quick-change dies or base plates for flexible production

- Compatibility with different foil types and materials

- Clear safety and operating instructions

- Accessible support or servicing from the manufacturer

Matching the Machine to Your Business Model

For Startups and Design Studios

If you’re just getting started, a manual hot foil machine is a great entry point. It offers low energy usage, but still enough capability to produce beautiful, well-finished work. Look for something compact, reliable, and easy to maintain.

For Growing Artisan Brands

When volume begins to increase, or your range expands across more product types, a semi-automatic or pneumatic machine might be more appropriate. These presses provide faster operation, and increased consistency, especially across longer runs.

For Print Professionals

If your business is focused on print finishing or high-volume production, you’ll benefit from the advanced features of a pneumatic or air-assisted press. These machines deliver repeatable results with speed and accuracy, allowing you to meet demand without sacrificing finish quality.

Why Choose a Metallic Elephant Hot Foil Machine?

We are the only company in the UK that designs and builds hot foil machines by hand and to order. Our presses are used by small businesses, designers, and packaging specialists across the country who rely on their machine to deliver quality work every time.

Here’s what makes our machines different:

- Built in the UK using traditional engineering principles

- Designed for tactile consistency, and durability

- Available in manual, semi-automatic, and pneumatic configurations

- Supported with custom dies, foils, accessories, and servicing

We understand the pressure that small businesses face when investing in equipment. That’s why we work closely with each customer to ensure they choose the right machine from the start, and that it continues to meet their needs as they grow.

Making the Right Decision

Choosing a hot foil machine is about finding a reliable, well-built press that suits how you work and what you produce.

A hot foil machine becomes part of how your business delivers quality. The right machine will support your workflow and help your products stand out. Whether you’re printing in small batches or scaling up production, investing in a machine tailored to your needs will pay off in both output and brand consistency. If you’re looking for practical advice, tailored recommendations, or want to explore our range of hand-built British-made hot foil machines, get in touch.