The search for unique print finishes often leads designers and printers back to high-quality techniques. Debossing is one of two traditional processes that turns simple paper or board into something memorable. This technique involves pressing a die into the material, sinking the design below the surface and creating a beautiful, indented effect.

What’s the Difference Between Embossing and Debossing?

Both processes use pressure and a metal die to alter the paper’s surface, but the finished result can change entirely. Embossing raises a design above the paper surface. The texture lifts away from the material, creating a highly impactful finish.

Debossing offers the opposite, inverted effect. The design is pressed into the material, creating a depression. The indented texture is often considered more understated and elegant. The difference in feel and look dictates which finish best suits the message and the material.

How Can Designers Achieve a Perfect Debossing Finish?

Achieving a premium result requires careful consideration from the earliest design stage. The process starts with the design file itself and a deep appreciation for the craft. Designers must treat the selected stock as an integral part of the final artwork as the chosen material’s weight and fibre directly influence how clearly and deeply the impression registers. Thicker boards hold the impression for longer, offering a clean edge that does not fade over time.

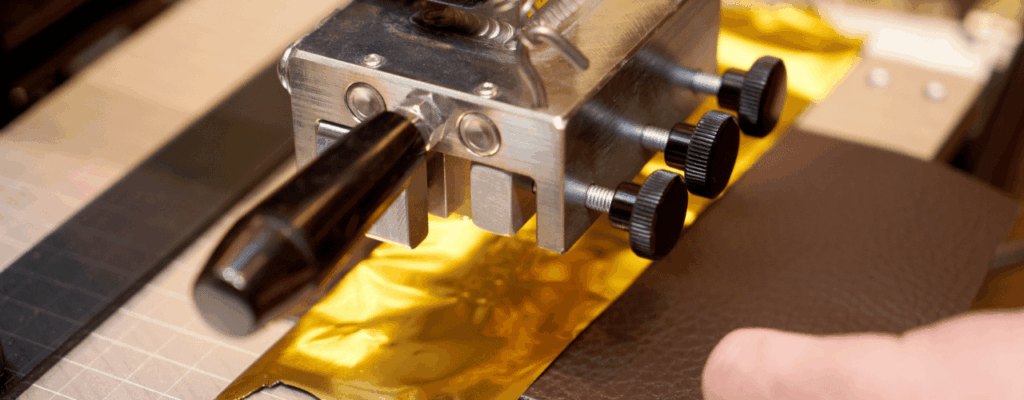

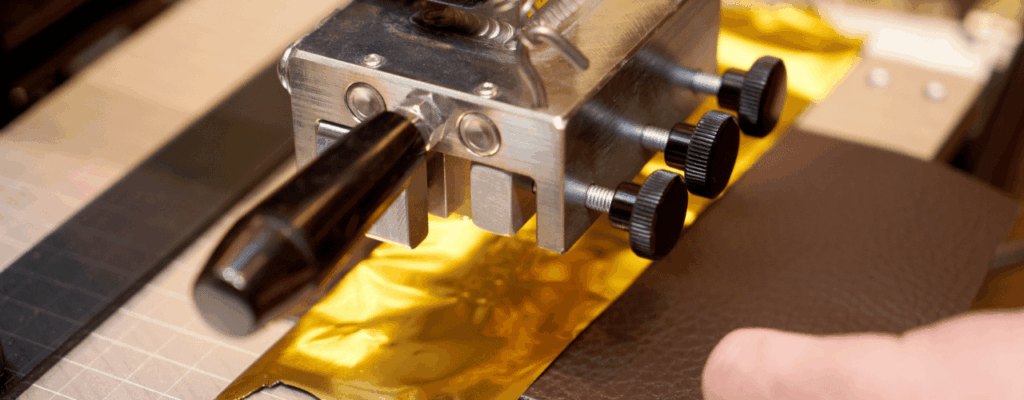

Selecting the right machine is equally important. A precision-engineered hot foil press gives you absolute control over the heat, contact time, and pressure.

Here are the critical factors that support a lasting finish:

- Material Selection: Opt for paper stocks that have a higher percentage of cotton as they can hold the shape better, allowing for deeper and more intricate debossing

- Die Quality: Only high-quality brass or magnesium dies should be used. A die made with precision engraving is necessary to guarantee every line and curve registers perfectly under pressure

- Pressure Management: The applied force must be uniform across the entire die area. A well-built machine guarantees prevents warping or inconsistent sinking

Why is Hand-Built Machinery Better for Precise Debossing?

The machinery used in print finishing is an extension of the crafter’s skill. For debossing, the press quality impacts the impression quality. Unlike mass-produced alternatives, the hot foil presses we design and build by hand in the UK are constructed with an unparalleled focus on the pressure mechanics. This dedication to British engineering ensures every machine meets a benchmark for quality and control.

Starting with a high-quality machine means you begin with exceptional print from the start. Debossing requires equipment capable of sustained, even pressure across the entire platen area. Our expertise, derived from decades spent working on the finest hot foil equipment, means we understand what it takes to build a press that delivers it.

How to Combine it with Hot Foiling

Premium print finishes truly excel when they work with other elements. Although a simple blind impression, where no foil or ink is used, makes a statement itself, introducing colour and a metallic glow improves the final piece further.

Often referred to foil blocking, the process typically involves two stages or a single pass with a specialised assembly die. First, the hot foil stamping applies the metallic finish to the design area. Then, the press action forces the foil-applied area down into the paper.

What Considerations Guide the Final Design Choices?

Making the final design requires a practical knowledge of how paper reacts under heat and pressure. Designers must consider the size, density, and intricacy of the design.

Here is what influences the final impression:

- Design Size: Large, solid areas of debossing require more significant pressure and a thicker stock to prevent ghosting or bruising on the reverse side of the paper

- Fine Detail: Conversely, fine lines and small type need an extremely precise die and controlled contact time to prevent the material from being crushed

- Die Material: The choice between magnesium for fine detail or brass for maximum service will also influence the look and feel of the texture

That knowledge guides the design process, making certain that the chosen design is manufacturable to the highest standard. It removes uncertainty, replacing it with engineering confidence.

Frequently Asked Questions

Does the type of paper matter?

Yes, the paper stock is one of the most important variables. Thicker, softer paper stocks are ideal because they compress cleanly and hold the impressed shape without tearing or developing stress marks. Materials that are too thin or heavily coated can often tear or show the impression through the back.

Is it the same as letterpress printing?

No. Letterpress is a method of relief printing where the raised surface of a plate or type is inked and pressed into the paper. Although both create an indentation, letterpress applies ink to the indented area.

Can I deboss a design and then foil block the same area?

Absolutely. Joining foil blocking with the indentation creates a highly premium finish. The result is achieved either through a single-pass combination die or a two-step process where the foil is applied first, followed by the pressure of the press die to create the indentation.

Start Your Next Project

Creating printed material that genuinely connects with its audience requires a commitment to quality. The selection of equipment, the material, and the precision of the die all contribute to an outcome that makes your work stand out. Debossing is a process that proves the value of artisanal techniques today, providing something that digital alternatives simply cannot replicate.

Our commitment to hand-built quality and unrivalled industry expertise defines what we do. We pride ourselves on offering personal service and equipping our clients with the finest tools, like our range of hot foil presses, to master these techniques. Experience the difference precision makes. Contact us today to discuss the perfect machine for what you require.