Designers often look for ways to give their projects an edge, and one finishing technique continues to deliver impact. Hot foil creates a striking look that digital or offset print cannot reach. When applied correctly, it turns packaging, stationery, and branded goods into products that feel premium and memorable.

Many creative teams can benefit from mastering this process. Learning the finer points of the craft helps reduce errors and improve consistency, creating work that leaves a strong impression.

What Should You Consider Before Starting a Hot Foil Job?

Preparation shapes the outcome of any foiling project. Start by asking yourself whether the design is suitable for foil application. Large solid areas may look uneven if the foil is not handled correctly, while very thin lines can fail to transfer. Simplify artwork into shapes and details that the foil can reproduce cleanly.

Stock choice is another important factor. Smooth and coated boards usually produce sharper results than textured ones. If you want to use a rougher surface, test a small batch first to confirm how well the foil adheres.

Thinking about these considerations before production helps avoid costly mistakes and ensures that the final product shows the best that foiling can achieve.

How Can You Optimise Artwork for Hot Foil?

Artwork needs to be prepared with precision. Vector files provide cleaner edges and scale without loss of detail. But avoid relying on gradients or shading effects, as foil is a solid transfer that does not allow for tonal variation.

Spacing plays a role too. Leave enough room around foiled areas to prevent heat and pressure from causing distortion. Keeping designs away from folds or die-cut edges reduces cracking.

A short proof run is often the best way to confirm that artwork is suited to hot foil production before committing to a larger batch.

Which Materials Work Best?

Not every surface takes foil in the same way. Some plastics and coated materials can work, but only with foils designed for those surfaces.

Certain recycled stocks can vary in quality, meaning adhesion may be inconsistent. Whenever you’re using an unfamiliar material, carry out a test to be sure the result matches expectations.

The best outcomes come from pairing the right foil with the right substrate, ensuring both are suited to the equipment and conditions used.

How do Temperature and Pressure Affect the Finish?

There is no doubt that these two variables influence foiling application. Too much heat can cause the foil to bubble, while too little leaves incomplete transfers. Pressure that is too high can flatten details, while pressure that is too low may leave patchy coverage.

The ideal balance depends on the foil, the substrate, and the machine. Keeping careful notes of your settings during each run helps you replicate results consistently across projects.

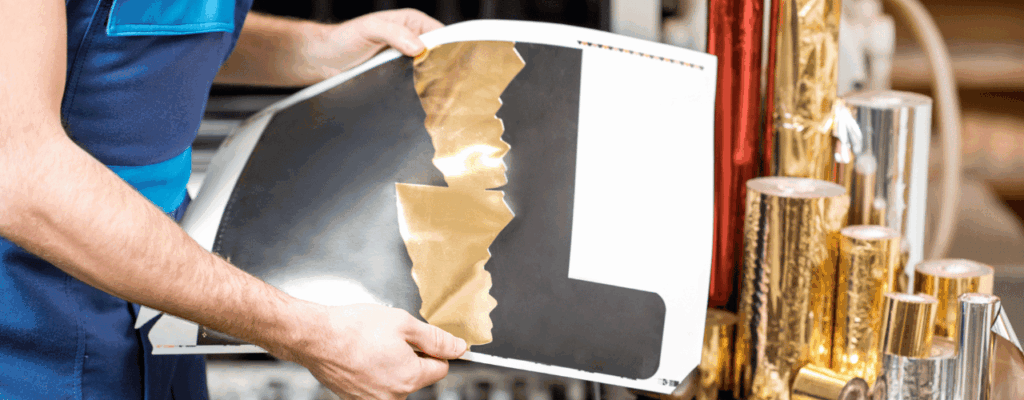

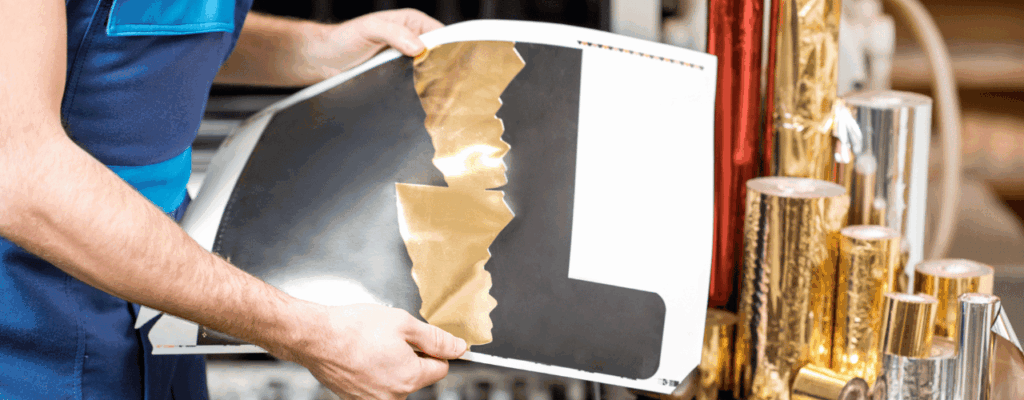

What Should You Know About Dies?

The die is the engraved plate that transfers foil onto the surface. Brass dies are durable and handle intricate designs well, making them ideal for longer runs. Magnesium dies are less costly and suitable for short projects.

Selecting the right die material is as important as choosing the foil itself. A high-quality die ensures sharp details and reduces the risk of misprints.

How Can Foil Colour Choices Transform a Design?

Colour choice sets the mood of any project. Metallic gold and silver are timeless, but there are many alternatives. Matte foils can add subtlety, while holographic options create intrigue.

Think about contrast too. A dark background with bright foil draws immediate attention, whereas tone-on-tone pairings are more sophisticated. Choosing the right colour for the intended audience ensures that hot foil becomes part of the message.

Should it Only be Used for Logos?

Foil is often associated with logos, but its potential is much wider. Designers can use it to highlight borders or for typography. It can also be applied to less obvious elements like product seals. These touches show care in areas that customers may not expect.

How Can Finishing Touches Improve Hot Foil Work?

The effect of foiling does not end once the impression is made. Adding finishing touches such as embossing, spot varnish, or careful edge trimming can take your project to another level. These refinements emphasise the foil and create layers of detail that truly stand out.

Considering finishing touches during the design stage ensures that they complement the foil rather than compete with it. This helps the final piece feel polished and intentional.

Keeping a Foiling Machine Running Smoothly

Consistent results rely on well-maintained equipment. Cleaning the platen and rollers prevents build-up that can interfere with transfers. Checking alignment and pressure settings avoids unnecessary faults. Scheduling routine servicing extends the life of the machine.

All of this together means that looking after the press ensures it performs reliably across multiple projects.

How to Get Started

Beginners shouldn’t be intimidated by foiling. Start with simple projects and build confidence. Experiment with different foils and stocks to learn how each variable affects the finish and keep notes on what works and what doesn’t.

Suppliers and machine makers often provide guidance and training. Over time, you’ll develop a workflow that makes hot foil a natural part of your creative process.

What New Opportunities Does Hot Foil Open Up?

Hot foiling is not only for luxury packaging or invitations. Designers are applying it to limited-edition prints and experimental art projects too. Each new application shows how adaptable the technique can be. Exploring these opportunities allows you to discover unexpected ways on how to use foil.

Why do Professionals Rely on it For Standout Results?

Professionals often turn to hot foil because of the finish it delivers. It adds prestige to projects and helps capture attention.

Strengthen your design portfolio and create projects that resonate. Now is the time to embrace foiling with Metallic Elephant. With the right techniques, you can achieve results that consistently impress.