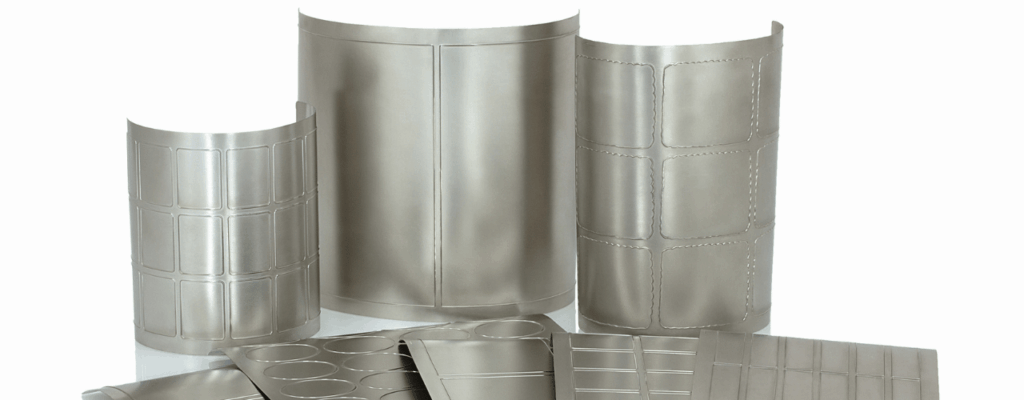

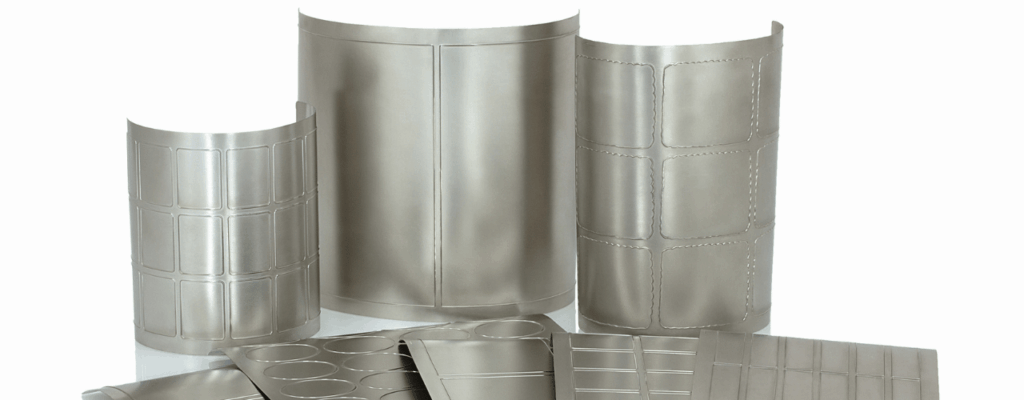

Print quality starts at the plate. With photopolymer plates, small fonts stay clear, and lines hold their shape, making them ideal for creators who want fewer misprints and a smoother process. We make plates in‑house, so advice and production sit under one roof.

How Are Photopolymer Plates Made?

UV exposure sets the image on a light‑sensitive sheet. Areas blocked by solid black film stay soft during exposure and wash away in water, leaving a raised image. That process is quick for simple jobs. We can provide steady results with clear guidance on setup, especially for more complex artwork.

What we check during making:

- Keeping light output steady with timed exposure and regular lamp checks

- Holding the film tightly against the plate so edges stay clear during exposure

- Removing dust before exposure and covering plates while they dry

How do Plates Improve Letterpress Impressions?

A well-made plate surface transfers ink and helps the sheet take a clear impression, giving a raised image that meets the stock evenly, so edges look clean rather than ragged. This matters on coated papers where any roughness shows. With photopolymer plates, you can consistently match each run.

How to Choose the Right Plates

Pick plates that suit the style of work you create most. Fine detail and a small typeface benefit from a plate surface that stays level under any pressure. Large areas look better when it stays uniform on textured cards. Share your most common stock and image size when you order so the plate you receive meets the sheet true and straight.

What Should You do to Prepare Artwork for Letterpress?

Set the typeface above 6pt when the stock is soft. Open small letter holes slightly so they do not fill in. Large solid areas on smooth stock are easier to work with when the design avoids long unbroken edges. A full‑size proof helps you spot what changes need to be made before you order.

Before you export files:

- Use vector paths for logos and text where possible

- Use solid black for areas that should print, avoiding tinted blacks

- For bitmap art, export at a high resolution so detail stay intact

- Simplify artwork so effects and outlines are saved as plain shapes

If you want a second pair of eyes, send files to our plate team. We will flag anything that could soften detail and suggest a simple fix.

How do Plates Behave on Cotton and Textured Papers?

Cotton paper compresses easily, so thin lines need only light pressure to print cleanly. Textured sheets need careful backing, so the plate surface reaches into the texture without marking it. You should check the coverage under a bright light before starting a longer run. Using the same test method each time shows how photopolymer plates perform across different surfaces.

What Problems do Photopolymer Plates Actually Solve?

If blurred edges occur, that typically points to unequal contact. A new plate with a level surface prints clean edges on the first print. Uneven ink suggests trapped air or movement, but secure clamping in the plate holder reduces that risk. Repeated alignment issues often comes from poor mounting rather than the press itself so a square trim and secure mounting tape should stop that from happening. Across common faults, well-made plates reduce guesswork and give you a clear understanding of how to fix it.

How Should You Clean and Store Them After a Job?

Wipe ink while still fresh using a soft cloth and a mild wash suited to your inks. Keep liquids away from edges so the adhesive layers stay intact. Lay plates on a level surface to dry, then file them in sleeves away from heat and sunlight. Label plates by job name, date, and stock so repeats start faster. With clean photopolymer plates, you save time whenever you next print and avoid damage that could shorten plate life.

How do You Order Plates for a Perfect First Run?

Send artwork at its final size and tell us the press model and stock you plan to use. We will make foil-backed polymer plates, cut to either 0.95mm or 1.52mm, and share simple guidance on how to use them. When your plates arrive, mount them square on a clean base and pull three test prints on the job stock. Adjust only one variable at a time until it looks right.

Who Gets the Most from Photopolymer Plates?

Independent creators who personalise leather goods gain clean marks with consistent placement. Wedding stationers also value how small fonts stay clear on invitation papers. Brand owners running short batches for launches use our plate service to match later reprints to the first run.

What Support Can You Get with Metallic Elephant?

We make photopolymer plates in‑house. If you send us artwork, our team will check the files, suggest a starting impression approach, and make plates that are ready to mount.

Every plate we ship is carefully checked before it leaves our workshop. Each one is packaged in protective sleeves that stop damage during delivery. With our fast turnaround time, you can also trust that every plate you receive has been tested and inspected by a team that cares.

You should be able to see obvious Improvements, starting with:

- Fewer test pulls before you reach a print you are happy with

- Cleaner edges on small logos

- A clearer starting point from our plate team, so you spend less time trialling settings

Want Help Choosing Plates for Your Projects?

We make photopolymer plates that fit the way you work. Tell us about your stock, artwork, and press, plus the products you make. We will prepare plates to suit and provide simple guidance on how to care for them. With the right photopolymer plates, your next letterpress run will look clean and consistent.

Contact us today.