Short-run print jobs are a common reality for small businesses and independent makers. If your project involves producing custom packaging, the need for high-quality results without the complexity or cost of large-scale production is increasing. Photopolymer plates offer a practical solution by delivering consistent results with fast turnaround and manageable setup costs. They provide a level of detail and reliability that makes them especially useful when working with tight budgets and shorter lead times.

What Are Photopolymer Plates?

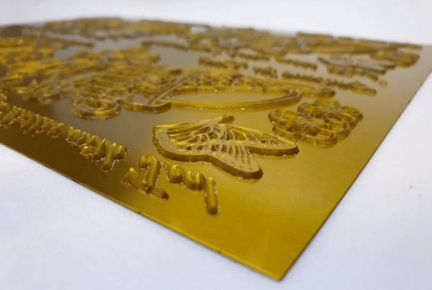

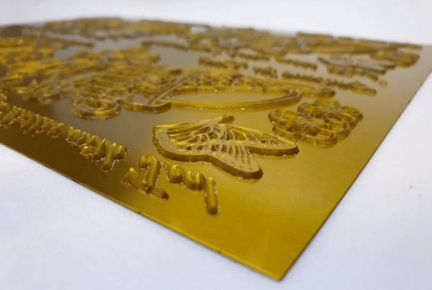

Photopolymer plates are light-sensitive printing plates used in letterpress, foil stamping, and flexographic printing. They are created by exposing a photosensitive polymer to UV light through a negative film. The areas exposed to light harden, while the unexposed areas are washed away, leaving a raised design that can be inked or used for impression-based printing.

These plates are typically mounted onto a base and used on flatbed presses, offering a reliable and repeatable surface for consistent results across multiple prints.

Why Photopolymer Plates Work Well for Short Runs

Short-run jobs often require a careful balance between quality and cost-efficiency. Photopolymer plates strike that balance well. They can be produced quickly, often within a day, which makes them ideal for fast-turnaround projects. Their lower setup costs compared to traditional metal dies also make them more accessible for businesses producing in small quantities.

Despite being more affordable, photopolymer plates offer sufficient durability to maintain consistent print quality throughout the entirety of a short run. Their ability to capture fine lines and small text also means there’s no need to sacrifice detail for budget. For businesses working on tight deadlines or limited editions, photopolymer plates are a smart, reliable solution.

Use Cases for Photopolymer Plates in Small-Scale Work

Photopolymer plates are frequently used by:

- Stationery designers producing bespoke invitations or business cards

- Small packaging runs for artisan goods, skincare, or food brands

- Custom event materials such as menus, name cards, or certificates

- Prototype packaging where high quality is needed without full production costs

For any project that involves multiple variants, names, or styles (for example, personalised wedding invitations), photopolymer plates allow for quick changes without high setup costs.

Comparing Photopolymer Plates with Metal Dies

While brass and magnesium dies are well known for their longevity and suitability in hot foil stamping, they are generally more costly and time-intensive to manufacture. For short-run work, that cost is often hard to justify.

These plates offer a practical alternative. They can be produced much faster than metal dies, which is helpful for projects working to tight deadlines. Cost-wise, they’re more accessible when the design won’t be reused extensively. For jobs that benefit from flexibility, rapid prototyping, or simple cost control, they allow for designs to be tested and revised with minimal waste or delay.

That said, for larger print runs or jobs that require ongoing repeat use, traditional metal dies still provide better long-term value. But for time-sensitive, budget-conscious projects, they clearly stand out.

Key Considerations When Using Photopolymer Plates

To get the best out of these plates, it’s important to understand their strengths and limitations:

- Storage and handling: They are more sensitive to temperature and handling than metal dies. Plates should be kept flat and away from direct light and heat.

- Press compatibility: Not all machines are equally suited to photopolymer use. At Metallic Elephant, we can advise which of our hot foil presses are best configured for this kind of plate.

- Design preparation: High-contrast, vector-based artwork delivers the best results during plate exposure.

Photopolymer plates are also not ideal for highly textured surfaces. In those cases, a traditional die or deeper etched plate may be preferred.

Efficiency and Waste Reduction

Small businesses are increasingly focused on reducing material waste and lowering energy consumption, and these plates support those goals effectively. On-demand production is a major benefit, as it allows creators to print exactly what they need, when they need it, without committing to large volumes or excessive inventory.

Short runs also help reduce waste. With better control over quantities and clearer expectations around print output, there’s less risk of overproduction. Additionally, the consistency of these printing plates means fewer errors during production, leading to fewer reprints and reduced material use. This combination of precision and efficiency makes photopolymer plates a strong option for environmentally conscious brands.

Why Photopolymer Plates Are Popular With Small Brands

For brands working with limited budgets or offering highly personalised products, they are a flexible tool that keeps turnaround time and cost under control. They allow makers to deliver print finishes that feel crafted and considered, rather than mass-produced.

They also support brand experimentation. Trying out a new logo finish, label layout, or packaging element becomes less risky when the cost of producing a plate is so manageable.

How Metallic Elephant Can Support Photopolymer Plate Printing

Although Metallic Elephant specialises in hand-built hot foil machines and precision brass and magnesium dies, we recognise the value these plates bring to specific workflows. Many of our customers use both, depending on the nature of the job.

Our hot foil presses are compatible with plate setups, and we regularly help customers configure machines for quick-change or mixed-use projects.

We also offer:

- Expert advice on plate compatibility and base alignment

- Maintenance guidance for consistent impression quality

- Reliable accessories to support short-run print tasks

For small studios or startups looking to expand their capabilities, this flexibility can open the door to more varied and creative work.

Making the Right Choice for Your Print Project

Photopolymer plates offer a practical, efficient route to high-quality printed finishes in short-run settings. While not a replacement for metal dies in every situation, they enable experimentation, reduce waste, and help smaller businesses present their products to a professional standard without unnecessary cost.

If you’re considering using photopolymer plates for your next project, or you’re looking for hot foil equipment that works seamlessly with them, contact us. We’d be happy to talk through your setup and help you find the right tools for your goals.